Injection Molding in Thailand is the Basis of Mass-production

Injection molding in Thailand has always played a large part in the industrial success of Thailand. It’s the backbone of the automotive industry as well as many other types of mass-production facilities in the country. Learn more about insert molding here.

While much has been made of the emergence of 3-D printing as the manufacturing wave of the future, the drawbacks of 3-D printing are many. The designers and engineers in the industries that use injection molding as part of their manufacturing process tend to stick with the tried and true applications of injection molding.

3-D Printing Has a Ways to Go

For 3-D printing to deliver the results and volume that injection molding in Thailand does, it will have to get a lot quicker and more efficient. 3-D printers are notoriously slow. They can only produce one product at a time. This is the main drawback of manufacturing that injection molding was created to solve.

By the time that a 3-D printer has finished printing a part, an injection molding machine can faithfully reproduce dozens of the same parts. The key is all in the creation of the injection mold.

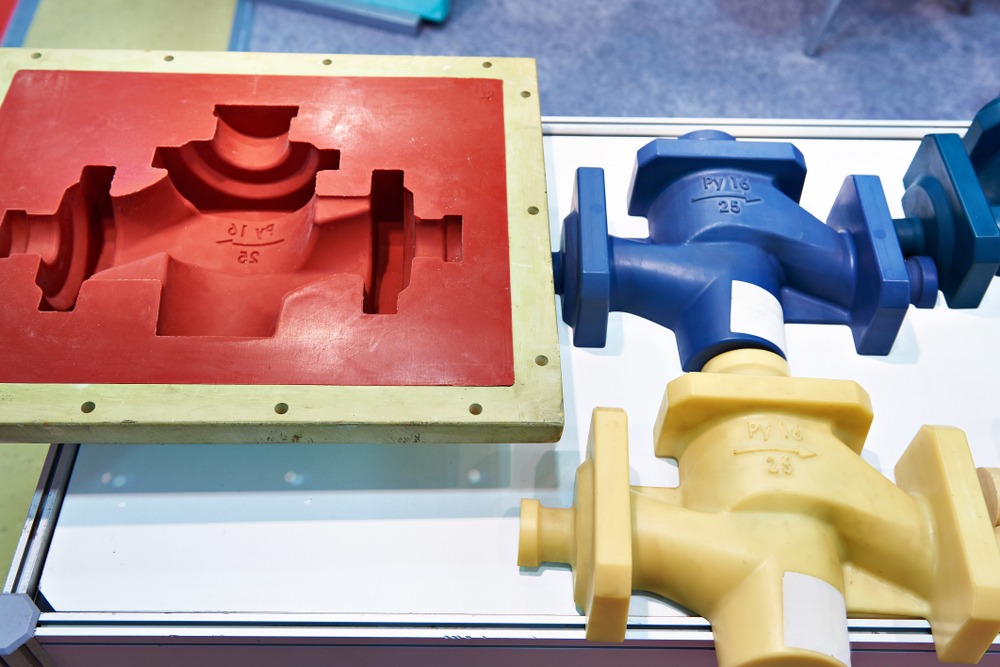

Exacting Engineering of an Injection Mold

An injection mold has to be engineered to the exact specifications called for by the designers and engineers of a product. It will be required to produce hundreds of exact replicas of a part throughout its service life. It has to reproduce the part correctly, right from the start.

A flawed injection mold can cost a manufacturer both considerable time and money. It can slow down the manufacturing process or bring it to a complete halt. This is why the people who create these injection molds are highly skilled individuals with a background in both engineering and industrial design.

The injection molds that these individuals create are highly valuable elements of the overall manufacturing process. The niche industry of injection molding in Thailand has long been a vital part of the entire industrial success for the country as a whole.

The Science of Mold-making

The industry of injection molding in Thailand comes down to the experience and knowledge of the mold-makers themselves.

Constructing a mold from the designs and specifications of manufacturing clients is an exacting science and one where the mold-maker has to look at the part both abstractly and functionally.

The mold-maker creates a reverse image of the part in the form of a mold. This mold will have to include points in it where the part’s material can be injected, without affecting the functionality of the resulting part. A well-designed and constructed mold becomes a part of a company’s assets. The value of the mold is calculated by the time and cost savings that it affords the manufacturer.

This is why injection molding in Thailand is unlikely to be affected by the interest in 3-D printing. The 3-D printer simply cannot measure up to the relative value and production capabilities of a well-designed and constructed injection mold in mass-production. And it’s unlikely that it ever will.

I’m a 20-something stay-at-home mother and wife. I have an amazing husband, a beautiful daughter, two loving dogs, and a lazy cat. I wouldn’t change my life for anything! I love to read, listen to music, cook and blog!

Speak Your Mind